- Author Nora Macey macey@family-relation.com.

- Public 2023-12-16 10:17.

- Last modified 2025-06-01 05:48.

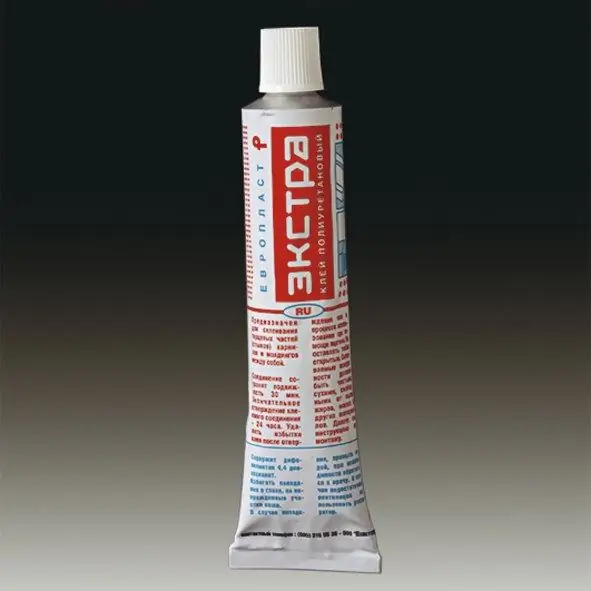

Polyurethane adhesive ranks at the top of the list of the best adhesives. It is used in many industries and is capable of bonding materials such as wood, metal, glass, ceramics, etc.

Today, polyurethane glue is one of the best modern adhesives. It is used in many spheres of human activity, in particular, furniture production, construction, mechanical engineering, etc. Polyurethane glue has a high adhesive ability, which allows it to be used for gluing almost any material - plastic, metal, silicate and organic glass, wood, expanded polystyrene, mineral wool, concrete, etc.

Adhesive properties

A feature of this adhesive material is the ability to expand in volume during curing. This slight foaming makes it possible to fill even the smallest gaps with material without displacing the surfaces to be joined. The adhesive bond is resistant to sudden temperature changes up to 40 ° C. It is not afraid of cryogenic temperatures, oil, gasoline, water, radiation and vibration. And due to the absence of odor and solvents in the product, you can achieve maximum safety during operation and environmental friendliness of processing. The polyurethane adhesive is resistant to mold and pathogenic fungi. It can be operated in a fairly wide temperature range from -60 to +120 ° C.

Adhesive characteristics

There are two types of polyurethane adhesives on sale: one-component and two-component. The one-part adhesives hardener with water, which makes the applicator easier to use. The two-component material is obtained by mixing compositions such as polyol and isocyanate. The latter type of adhesive is easy and convenient to use, and its high viscosity values provide excellent initial setting. When isacyanates interact with atmospheric moisture, a chemical reaction occurs, as a result of which cross-molecular bonds are formed, providing maximum bond strength.

Polyurethane-based adhesive is indispensable when laying parquet flooring. For this, as a rule, two-component formulations are used that do not contain solvents and water. The introduction of a hardener into the adhesive reduces the drying time of adhesive films, increases hydrolytic resistance and adhesive strength. Consumption depends on the material and is 150-500 g / m². Viability is due to modification and ranges from 1 to 4 hours. The polyurethane adhesive has a color ranging from beige to dark brown, and the shear strength of the bond depends on the types of materials being bonded and ranges from 2 to 26 MPa.