- Author Nora Macey macey@family-relation.com.

- Public 2023-12-16 10:17.

- Last modified 2025-01-23 08:48.

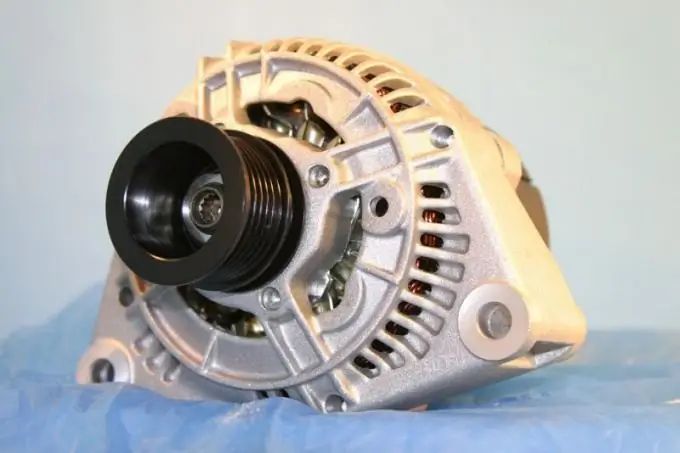

Domestic generators and generators of old foreign cars are not very complex in design and are suitable for repair on their own. The process of sorting out a generator is its complete disassembly, troubleshooting of parts, replacement of faulty components with new ones and subsequent assembly. Be sure to purchase a spare parts kit for your generator before overhauling.

Necessary

- - diode bridge;

- - capacitor;

- - bearings;

- - new nuts;

- - relay regulator;

- - universal puller;

- - wrenches;

- - chisel;

- - pliers;

- - brush for metal.

Instructions

Step 1

Remove the alternator from the vehicle and clean it with a brush. Remove the pulley retaining nut. To do this, put the generator so that it rests on the floor with the pulley, put a suitable wrench on the nut and apply strong and precise blows to the wrench with a hammer. With your other hand, keep the pulley from turning at the same time.

Step 2

Then unscrew the fastening bolts on the generator housing and remove the studs that tighten it. On the generator shaft, find the key that holds the pulley from turning and use a chisel to knock it out. To do this, place the generator with the shaft up, press the chisel into the key from top to bottom and apply light blows to the chisel with a hammer.

Step 3

Then remove the front cover of the generator. Then dismantle the relay controller. Use a punch to knock out the rotor through the hole under the removed relay. To do this, apply a few light blows and turn the rotor. Repeat the procedure until the rotor is completely removed.

Step 4

Unscrew the nuts securing the stator and diode bridge. If the bolts will turn, hold them with pliers on the opposite side of the cover. Remove the stator with light hammer blows. Then remove the diode bridge and unscrew the capacitor. Then press out the rear rotor bearing using a universal puller.

Step 5

Unscrew the pulling plates on the front cover. Replace locknuts with new ones if damaged. Support the bolts with pliers on the other side so that they do not twist. After removing the plates, press out the bearing through the mandrel.

Step 6

Check all removed parts for operability and clean them with a metal brush and sandpaper. Replace defective parts with new ones. Strip contacts from oxidation. Sand the condenser seating plane for better contact with emery paper.

Step 7

Reassemble the generator in reverse order. When pressing the rear bearing onto the rotor, install the mandrel only on the inner ring of the bearing. Pressing the front bearing onto the outer ring. Hammer the rotor with light hammer blows, pushing the head over the shaft to protect the thread. When assembling the front bearing pads, lock the bolts with a chisel.