- Author Nora Macey macey@family-relation.com.

- Public 2023-12-16 10:17.

- Last modified 2025-01-23 08:48.

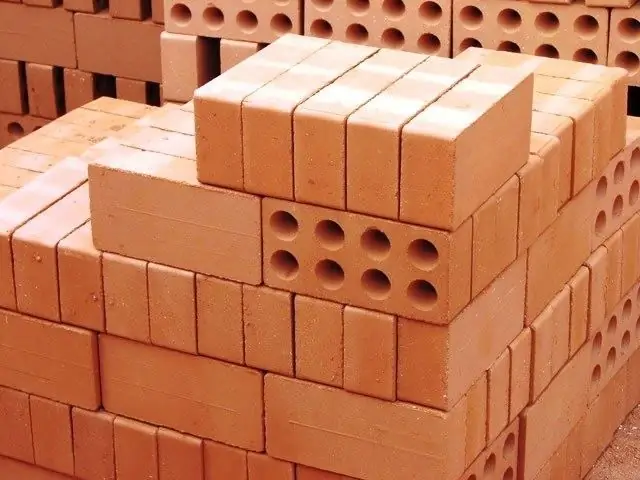

Brick is a stone made artificially from clay and water. These materials are used exclusively for the construction of various objects. Bricks vary in shape, color and strength. For the production of each type, special technologies and different types of clay are used.

Types of bricks

All bricks have high levels of water resistance, frost resistance and durability. Traditionally, these materials are divided into two categories - white and red. In fact, there are many more types of bricks. The most common of them are ceramic, silicate, hyper-pressed and adobe bricks.

The main difference between bricks is not in their shape, but in their composition. Building materials are made from clay or a mixture of sand and lime. In the first case, red bricks are obtained, and in the second, white bricks.

Brick production

Until the 19th century, bricks were made using a different technology. Each brick was formed by hand and then fired in small kilns. The modern brick making process includes three main stages. First, all the necessary materials are prepared - lime is made, sand and clay are mined. Materials are carefully processed and mixed into special compounds.

The clay is crushed using a special technique, resulting in a powder. It should be noted that only certain deposits are used for the extraction of this material. Not every type of clay is suitable for making bricks.

The second stage in the manufacture of bricks is the formation of the building material and its preliminary drying. The main feature of this process is the absolute elimination of air. Bricks are formed under very high pressure. First, the workpiece is a huge bar, and then it is cut into small pieces - the familiar bricks. Workpieces are dried in large chamber or tunnel dryers.

The last stage in the production of bricks is firing. This process is carried out in a special oven under the influence of a temperature of over 1000 degrees. It should be noted that the pressed materials must dry for several days before being sent to the oven. If you do this earlier, then the strength of the material will significantly decrease.

The quality of each batch of bricks produced is tested using a press. Several samples are subjected to a pressure of more than 50 tons. The material should not only withstand such a load, but also remain without damage in the form of chips or cracks. It is believed that the most important stage in the manufacture of bricks is firing. The waterproofness and strength of the material depend on this process.