- Author Nora Macey macey@family-relation.com.

- Public 2023-12-16 10:17.

- Last modified 2025-01-23 08:48.

In order to ensure the combustion of fuel in the boilers, it is necessary to constantly feed the boiler furnaces with air, as well as to ensure the unhindered emission of combustion products into the atmosphere. In cases where the resistance of boilers and gas lines is large, and it does not allow gases to move with the help of natural draft, an artificial (forced) draft is created.

Instructions

Step 1

Forced draft - removal of burned fuel residues using smoke exhausters (called "artificial draft of direct action") or supplying air under pressure to equipment that burns fuel. Also forced draft is used for exhaust ventilation in buildings.

Step 2

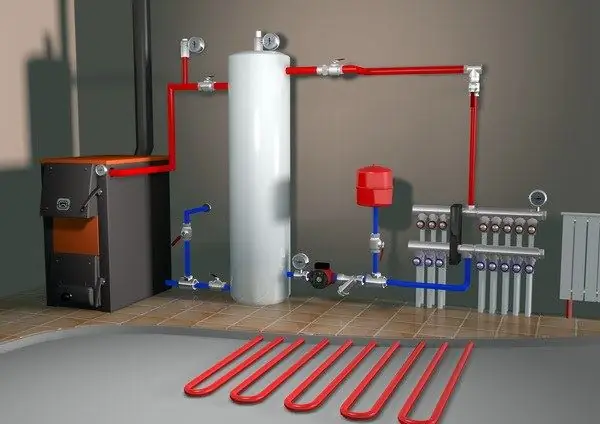

Fume extraction and air supply devices consist of exhaust fans, air lines, gas lines, fans that serve for forced air injection, and a chimney. With the help of this equipment, non-stop delivery of the required volume of air to the combustion chamber, the movement of flue gases along the gas ducts of the boiler device and their release into the environment are carried out.

Step 3

During operation, it was found out that it was necessary to blow in more air than indicated in the technical documentation. The fuel and air do not have time to mix completely in the firebox, and some of the oxygen does not burn, but is blown out of the boiler along with the combustion products. It follows from this that the power of the fans supplying air must be calculated for the maximum efficiency factor incorporated in the design of the boiler equipment. The same rule applies to smoke exhausters. Often, trying to save energy, they install exhaust pumps of the same type, but with a relatively small power and a lower number of revolutions of the electric motor, which significantly reduces the draft in the boiler.

Step 4

Insufficient draft in the boiler leads to unstable operation of the boiler equipment, the fuel does not burn completely and is released into the atmosphere, and this is fraught with subsequent clogging of the chimney with soot and ash particles, which in turn often forces the boiler to be stopped and cleaned. Also, incomplete combustion of fuel leads to burnout of insulating materials, and their frequent replacement increases the cost of operating the boiler. The decrease in draft also contributes to the fact that the room where the boiler is located is filled with smoke and this requires additional investments for the device of artificial exhaust in the building.

Step 5

The process of forced air supply and forced draft, organized according to the rules, significantly reduces losses in fuel underburning, increases the power of boiler equipment and increases its maintenance-free service life.