- Author Nora Macey macey@family-relation.com.

- Public 2023-12-16 10:17.

- Last modified 2025-01-23 08:48.

To make this or that product from metal, a variety of processing methods are used. One of them is metal cutting. Blanks and sheets are divided into parts not only with the use of heating, but also with other technological methods. The choice of the type of cutting is determined by the degree of complexity of the finished product and the availability of a suitable tool.

Metal cutting methods

When cutting metal, it is divided into parts in a predetermined place. One of the most common cutting methods today involves heat treatment of the cut site, that is, heating the workpiece. But mechanical, water-jet and laser action on metal is widely used.

Such cutting methods do not require exposure of the workpiece to a hot gas jet or torch flame. The metal is separated without heating. The methods of such cutting have not only advantages, but also disadvantages, which, however, can be compensated for by complex types of material processing.

Mechanical cutting of metal

The simplest and most common not only in everyday life, but also in production method of dividing metal blanks into parts is mechanical cutting. For these purposes, a hacksaw for metal, a band saw, a milling cutter, an angle grinder, and so on are used.

In industrial production, special-purpose machines are used, on which it is convenient and quick to mechanically cut metal sheets, pipes, profiles and some other semi-finished products from pure metals and their alloys.

The disadvantage of the mechanical method is its relatively low productivity. The working part of the tool used for such cutting is usually not very durable, it is easily dull and needs to be replaced frequently.

Difficulties also arise if it is required to mechanically cut a metal figure of a rather complex shape.

Laser cutting of metal

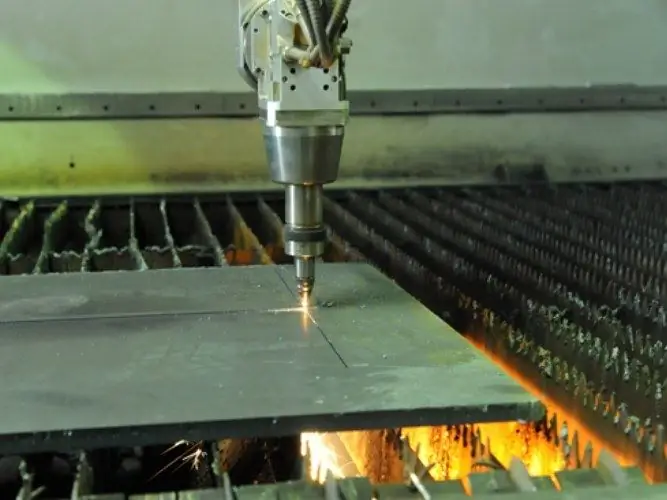

One of the modern cutting methods involves the use of a narrow laser beam. Such a beam can separate metals and various alloys from them, obtaining an extremely narrow cut while maintaining a minimum thermal effect in the working area. At the same time, the edges of the processed workpiece are very clean and practically do not have deformations, which are difficult to do without during mechanical cutting.

The laser beam has a high energy, which guarantees the highest possible productivity. The cutting device is easy to operate. The use of a laser makes it possible to manufacture parts of a very complex, and sometimes even very intricate shape.

Waterjet cutting of metal

Waterjet cutting of metal is one of the most efficient and accurate methods used to separate workpieces without heating. In this case, the metal being processed is influenced by a jet consisting of a mixture of sand and water.

The mixture is fed into the cutting zone under very high pressure through a special nozzle that looks like a narrow nozzle.

And in this case, the metal is not exposed to high temperatures, and therefore does not deform. The method is good in that it does not require processing the edges of the product after itself. A significant disadvantage of such processing is the relatively high cost. It is not recommended to use the waterjet method if the product may be sensitive to corrosion.