- Author Nora Macey macey@family-relation.com.

- Public 2023-12-16 10:17.

- Last modified 2025-01-23 08:48.

Among the huge number of varieties of copper cables, the VVG type is distinguished by high performance and safety; the cable is successfully used in explosive places, and in the event of a fire, its sheath does not support combustion.

The VVG cable is a power wire covered with an insulating PVC sheath. Its main field of application is electrical substations, cable racks, lighting, distribution devices, local networks. VVG cable is recommended for use when arranging a network in the open air.

VVG design

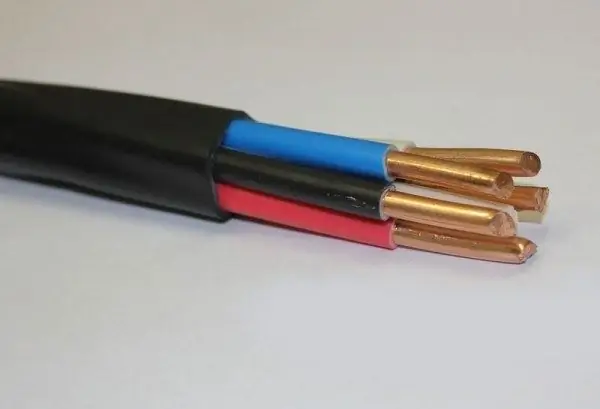

This product is a solid or stranded wire with a round or sector shape. The core is protected by polyvinyl chloride insulation - if the wire is stranded, then each core has a "personal" color. In this case, the neutral wire has blue insulation, and the grounding conductor is green-yellow. Multi-core products are formed into strands, which can have from 2 to 5 cores. If there are only two cores in the cable, then their cross-section will be the same; subject to the presence of several veins, one of them may have a smaller cross-section. Overall, the upper shell is also made of PVC.

There are several modifications of this cable. One of them - VVGng, - the last two letters mean that the product does not support combustion. There are also 2 more cable options:

- VVGng-LS: the product does not spread combustion and has a reduced emission of smoke and gas;

- VVGng-FRLS: the product is fire-resistant, does not spread combustion and is characterized by low gas and smoke emission.

The production of VVG cable implies strict adherence to strict design requirements: the PVC sheath must have high resistance to mechanical deformation in the temperature range of + 78-82C, the cable must resist winding. The service life of the product, subject to all operating rules, is up to 30 years.

Installation methods

Open cable laying on surfaces, structures made of materials such as brick, gypsum, concrete is allowed. Installation is also possible on suspended structures (for example, a cable), provided that no mechanical impact on VVG is possible. If there is a risk of damage to the cable, then additional protection is needed in the form of corrugated hoses, cable channels, pipes, etc. Another installation method is the use of cable support structures. These include boxes, cable trays, pipes. A similar installation method is typical for industrial premises, workshops.

VVG hidden gasket is used for installation in residential buildings. In this case, the cable is placed under plaster, in grooves, voids. In this case, additional protection is not required. The exception is wooden surfaces - in this case, the wiring must be placed in a sleeve made of non-combustible material. Laying VVG in the ground is not recommended. If there is a need for this, then the wire must be placed in a pipe, or a special tunnel.